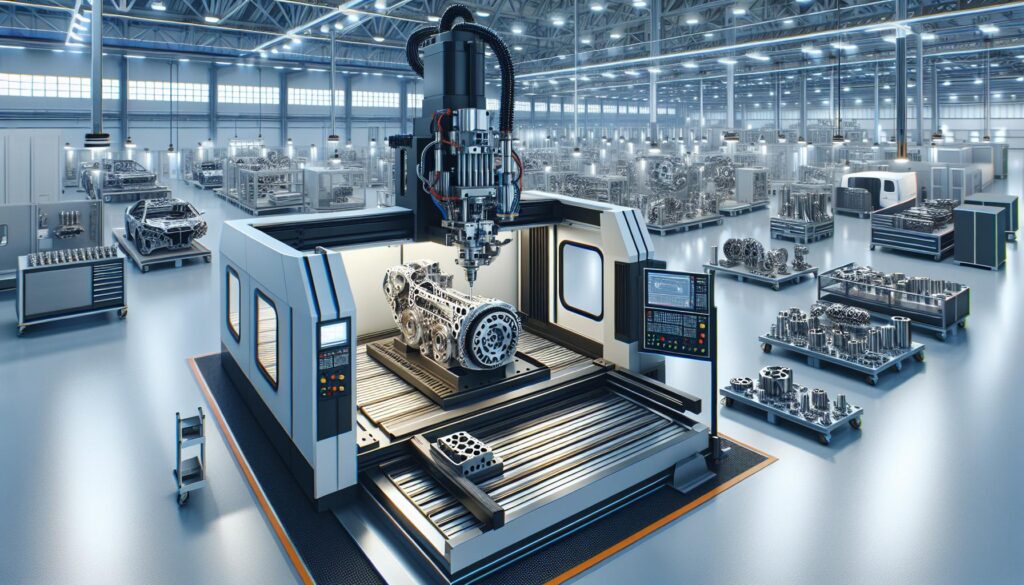

In the fast-paced world of automotive manufacturing, precision is key, and CNC machines play a crucial role in achieving it. These advanced tools can produce a wide range of components, from intricate engine parts to complex chassis elements. Understanding the types of components that can be created with automotive CNC machines not only highlights their versatility but also underscores their importance in enhancing vehicle performance and safety. For businesses looking to optimize their manufacturing processes, CNC Machining services from trusted providers like Yijin Hardware offer high-precision solutions tailored to meet the evolving needs of the automotive industry.

Overview of CNC Machines in Automotive Industry

CNC machines play a crucial role in the automotive industry, directly impacting the quality and efficiency of manufacturing processes. These computer-controlled tools create components with high precision, accommodating the stringent requirements of modern vehicle design.

CNC machines can produce a wide array of automotive parts, including:

- Engine Components: Parts such as cylinder heads, crankshafts, and camshafts require tight tolerances for optimal performance.

- Transmission Parts: Gearboxes and housings benefit from the accurate shaping and drilling capabilities of CNC machinery.

- Suspension Elements: Components like control arms and brackets are crafted with precision to ensure vehicle stability and safety.

- Chassis Parts: CNC machines can manufacture complex chassis elements that support vehicle structure while reducing weight.

- Interior Components: Dashboard panels, console parts, and trim pieces are often produced using CNC techniques for smooth finishes and fit.

CNC technology enhances productivity, reduces waste, and shortens lead times, making it a vital asset in automotive manufacturing. With continual advancements, these machines can be adapted for new materials and designs, ensuring they meet evolving industry standards.

Benefits of Using CNC Machines

CNC machines offer significant advantages in automotive manufacturing, enhancing both product quality and production efficiency.

Precision and Accuracy

CNC machines deliver high precision and accuracy in component production. They operate using computer-controlled systems, ensuring exact dimensions and tight tolerances. This precision minimizes the risk of human error during manufacturing. For instance, parts like cylinder heads and crankshafts can be produced with micrometer-level precision, improving overall vehicle performance.

Efficiency and Speed

CNC machines improve manufacturing efficiency and speed significantly. They can operate continuously with minimal downtime, leading to faster production cycles. The automation of complex tasks reduces manual labor, allowing for a quicker turnaround on high-volume orders. Additionally, CNC machines are capable of machining multiple components simultaneously, which further enhances throughput in automotive production.

Common Components Produced with Automotive CNC Machines

CNC machines play a vital role in automotive manufacturing by producing a range of essential components with precision and efficiency. The following outlines key types of components produced using these advanced machines.

Engine Parts

Engine parts, such as cylinder heads and crankshafts, are critical for vehicle performance. CNC machines create these components with micrometer-level precision, ensuring optimal fit and function. Each part undergoes meticulous machining processes, allowing for the intricate designs required for modern engines.

Transmission Components

Transmission components, including gearboxes and shafts, are produced to exact specifications. CNC machines enable manufacturers to achieve tight tolerances, essential for smooth operation and reliability. The automation of this process reduces production time and enhances the durability of transmission systems.

Chassis and Frame Components

Chassis and frame components, like control arms and crossmembers, benefit from the structural integrity provided by CNC machining. These machines enable the production of complex geometries while maintaining high strength-to-weight ratios, contributing to overall vehicle safety and performance.

Interior and Exterior Trim

Interior and exterior trim pieces, such as dashboard panels and body panels, utilize CNC technology to achieve consistent quality and finish. This production method allows for intricate features and designs, enhancing the aesthetic appeal of vehicles while maintaining durability and functionality.

Future Trends in Automotive CNC Machining

Advancements in automotive CNC machining continuously shape the industry. These innovations improve precision, efficiency, and sustainability in manufacturing processes.

Advances in Technology

Emerging technologies transform CNC machining in the automotive sector. Artificial intelligence optimizes machining processes by analyzing data for improved decision-making. Machine learning algorithms improve predictive maintenance, reducing downtime and increasing productivity. Additionally, additive manufacturing techniques integrate with CNC processes, enabling the production of complex geometries that traditional methods cannot achieve. Additionally, increased automation in CNC machining allows for greater consistency and speed in manufacturing, maintaining high-quality standards while meeting increasing demand.

Sustainability Practices

Sustainability practices become integral to CNC machining operations. Manufacturers focus on minimizing waste through efficient production techniques and alternative materials. Using recyclable materials and eco-friendly lubricants promotes environmental responsibility. Additionally, CNC machines improve energy efficiency by consuming less power during operations. Implementing closed-loop systems allows for material recycling, further reducing environmental impact. These sustainability initiatives not only fulfill regulatory requirements but also align with consumer preferences for eco-conscious automotive solutions.

Conclusion

CNC machines have revolutionized the automotive industry by enabling the production of a wide range of components with unmatched precision and efficiency. Their ability to create intricate engine parts and complex chassis elements is crucial for meeting modern vehicle design standards. As technology advances, the adaptability of CNC machines continues to improve manufacturing processes, ensuring they remain at the forefront of automotive innovation.

The integration of sustainability practices and smart technologies positions CNC machining as a key player in the industry’s future. By focusing on reducing waste and improving energy efficiency, manufacturers not only comply with regulations but also cater to the growing demand for eco-friendly solutions. This evolution reinforces the vital role of CNC machines in shaping the future of automotive manufacturing.

Frequently Asked Questions

What is a CNC machine in automotive manufacturing?

CNC machines, or Computer Numerical Control machines, are advanced tools used to automate the manufacturing process of automotive components. They produce precise parts essential for vehicle performance, ensuring tight tolerances and minimizing human error.

How do CNC machines improve vehicle performance?

CNC machines ensure high precision in producing critical engine parts, like cylinder heads and crankshafts. This precision enhances overall vehicle performance and safety by guaranteeing that components fit and function optimally according to design specifications.

What kinds of parts can be made with CNC machines?

CNC machines can create a wide variety of automotive parts, including engine components (cylinder heads, crankshafts), transmission parts (gearboxes), chassis elements (control arms), and interior components (dashboard panels), all with high accuracy and efficiency.

How do CNC machines impact manufacturing efficiency?

CNC machines enhance manufacturing efficiency by operating continuously with minimal downtime, automating complex tasks, and machining multiple components simultaneously. This leads to quicker turnaround times for high-volume orders and reduced production waste.

What are the future trends in CNC machining for the automotive industry?

Future trends include advancements in artificial intelligence and machine learning for decision-making and predictive maintenance, increased automation for consistency, and sustainable practices that focus on minimizing waste and improving energy efficiency in CNC operations.